Choosing the right whiskey bottle size is not just a packaging detail. For many brands and distilleries, it is a business decision that affects how your product is seen, sold, and shipped.

Different glass bottle sizes for whiskey can change how your brand stands out on the shelf. A compact bottle may feel modern and premium, while a larger format often signals value and volume. The size you choose also impacts export compliance, especially when you sell whiskey across different markets with specific volume standards.

Bottle size plays a role in logistics cost as well. Heavier or oversized whiskey bottles increase shipping weight, pallet efficiency, and breakage risk during transport. Over time, these factors directly affect your total packaging cost.

Most importantly, whiskey bottle sizes influence brand positioning. Whether you are launching a craft whiskey, expanding into duty-free, or scaling a core product line, the bottle size you select sends a clear message to your buyers. Understanding how different whiskey bottle sizes are used in the industry helps you make smarter packaging decisions from the start.

Standard Whiskey Bottle Sizes Used Worldwide

When you look at whiskey bottle sizes used around the world, you will notice that most brands follow a set of industry standards. These standard whiskey bottle sizes exist for a reason. They help brands meet local regulations, simplify production, and reduce supply chain risks.

For you as a brand owner or buyer, using common whiskey bottle sizes makes sourcing glass bottles easier and more cost-effective. Standard sizes are widely supported by glass bottle manufacturers, closure suppliers, and filling lines. This also gives you more flexibility when you scale production or enter new markets.

Below is an overview of the most common glass bottle sizes for whiskey and how they are typically used in different regions.

| Bottle Size | Common Use | Key Markets |

| 50ml / 100ml | Sampling, travel retail, tasting kits | Global |

| 375ml | Gift sets, limited releases | US, Asia |

| 700ml | Standard retail size | Europe |

| 750ml | Mainstream retail size | US, Asia |

| 1L | Duty-free and travel retail | Global |

| 1.75L | Value retail and bulk formats | North America |

Whiskey Bottle Sizes by Capacity and Market Compatibility

When you source glass bottles for whiskey, size compliance is one of the most common risks in cross-market supply. Different regions follow different volume standards, and choosing the wrong bottle size can limit where you are allowed to sell.

In the European Union, 700ml is the officially recommended standard for retail whiskey. Most EU distributors and filling lines are built around this size. In the United States, 750ml remains the dominant and most widely accepted format. Japan, on the other hand, shows a strong preference for 500ml and 350ml short bottles, especially for domestic retail and gift-driven products.

Understanding how each bottle size fits into these markets helps you avoid rework, relabeling, or restricted distribution later.

50ml and 200ml: Mini Whiskey Bottle Sizes

Small whiskey bottle sizes like 50ml and 200ml are widely used for tasting sets, promotional packs, and gift programs. These sizes are generally accepted across markets, making them suitable for global campaigns.

For gift-focused brands or marketing teams, mini glass whiskey bottles offer lower glass weight, reduced logistics cost, and strong visual appeal. However, customization options may be more limited, and minimum order quantities are usually higher due to filling efficiency requirements.

Best for: gift brands, sampling programs, limited editions

Market compatibility: global

Logistics: lightweight, cost-efficient for air and parcel shipping

375ml and 500ml: Flexible Sizes for Small-Batch Production

375ml and 500ml whiskey bottles are often chosen by startup distilleries and craft brands. These sizes allow you to test new products without committing to large production volumes.

In Japan and parts of Asia, 500ml bottles are especially popular and well accepted by consumers. For emerging brands, these mid-size formats offer better customization flexibility and lower overall risk compared to full-size bottles.

Best for: startup distilleries, pilot runs, regional brands

Market compatibility: US, Asia, Japan

MOQ & customization: easier to customize, moderate MOQs

Logistics: balanced weight and pallet efficiency

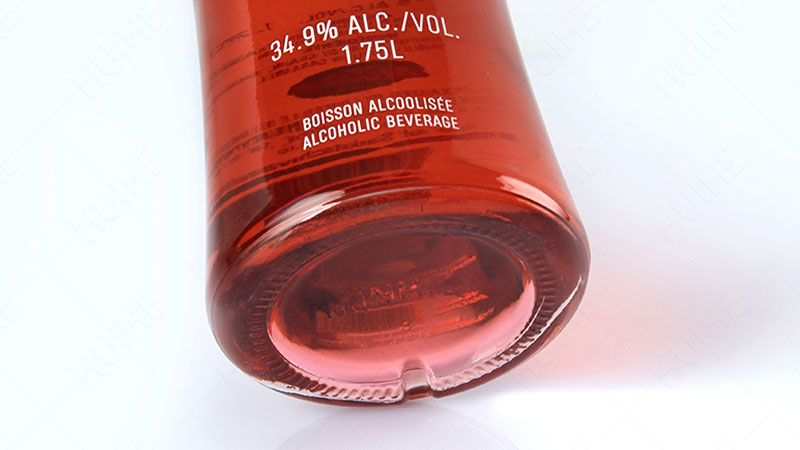

1L and 1.75L: Large Formats for Volume and Duty-Free

Large whiskey bottle sizes such as 1L and 1.75L are mainly designed for duty-free and value retail channels. These bottles are common in airports and North American markets, where larger formats signal value and long-term consumption.

From a sourcing perspective, these sizes require stronger glass structure and careful weight control. Shipping costs are higher, but unit cost per milliliter is usually lower.

Best for: mature brands, duty-free, volume retail

Market compatibility: global (1L), North America (1.75L)

Logistics: higher shipping weight, lower cost per unit volume

700ml vs 750ml: Choosing the Right Standard Size

For most established whiskey brands, 700ml and 750ml remain the safest and most scalable options. These sizes align with regional regulations and offer the widest support from glass bottle manufacturers and filling lines.

If you plan to supply both EU and US markets, it is critical to confirm whether a single bottle design can support both volumes, or if separate SKUs are required. Making this decision early helps you avoid compliance issues and unnecessary tooling costs.

By aligning whiskey bottle sizes with regional standards and your brand stage, you can reduce compliance risk, control logistics cost, and build a more reliable supply chain.

750ml vs 700ml Whiskey Bottles: What Else Brands Need to Know

The difference between 750ml and 700ml whiskey bottles may look small, but for brands selling across borders, it matters a lot. These two sizes are both considered standard whiskey bottle sizes, yet they follow different regulatory systems.

In the United States, 750ml is the long-established retail standard. Most filling lines, labeling systems, and distributor expectations are built around this size. In the European Union, 700ml is the officially recommended format under EU spirits regulations. Using the wrong bottle size can limit where your whiskey can be legally sold.

For export-focused brands, this creates a key question: do you need two separate bottle designs, or can one glass bottle work for both markets?

From a manufacturing point of view, 700ml and 750ml whiskey bottles do not always share the same mold. While the external shape may look identical, the internal volume, fill height, and weight distribution often differ. This means a “one-size-fits-all” mold is not always possible, especially for bottles with heavy bases or complex profiles.

That said, some glass whiskey bottle designs can be engineered to support both 700ml and 750ml volumes using the same outer bottle shape. In these cases, the capacity difference is achieved by adjusting the internal cavity or base thickness. For you, this approach can reduce tooling costs and simplify inventory management.

However, this option is not suitable for every design. Export brands need to confirm early whether a shared mold meets both EU whiskey bottle regulations and US filling requirements. Neck finish compatibility, fill level markings, and labeling rules must also be checked before mass production.

If your brand plans to sell whiskey in both EU and US markets, choosing between 700ml vs 750ml whiskey bottles is not just a sizing decision. It is a supply chain and compliance strategy that should be planned from the start.

Large Whiskey Bottle Sizes and Their Packaging Considerations

Large whiskey bottle sizes such as 1L and 1.75L are commonly used in duty-free and value retail channels. For brands, the key question is not how much whiskey the bottle holds, but whether the packaging can perform safely and consistently through filling, transport, and retail display.

With 1L and 1.75L whiskey bottles, structural reinforcement becomes essential. As bottle volume increases, the stress on the glass body and base also increases. Without proper design, larger bottles are more likely to fail during pallet stacking or long-distance shipping.

Another important factor is the center of gravity. Tall or wide-shouldered large whiskey bottles can become unstable, especially on moving conveyor lines or retail shelves. An unbalanced design increases the risk of tipping, scuffing, and breakage during handling.

Shipping performance is also a major concern. Larger glass whiskey bottles are heavier, which raises the risk of transport damage if the bottle walls or base are not properly reinforced. In many cases, brands see a higher breakage rate with large-format bottles when standard glass thickness is used.

This is why heavy base whiskey bottle designs are often recommended for 1L and 1.75L formats. A thicker base improves stability, lowers the center of gravity, and helps absorb impact during transport. While a heavy base adds weight, it can significantly reduce breakage and improve overall packaging reliability.

For export brands, balancing glass weight, strength, and logistics cost is critical. Choosing the right structural design for large whiskey bottle sizes helps you protect your product, control damage rates, and maintain consistent supply across global markets.

How to Choose the Right Whiskey Bottle Size for Your Brand

Choosing the right whiskey bottle size is not only about how much liquid you want to sell. For most brands, it is a system decision that affects compliance, cost, and long-term scalability.

1. Target Market Regulations

Your first step should always be regulation. Different markets follow different standard whiskey bottle size rules. The EU favors 700ml, the US relies on 750ml, and some Asian markets accept smaller formats such as 500ml or 375ml. If you plan to export, choosing the wrong glass bottle size for whiskey can create relabeling issues or limit where your product can be sold.

You should define your primary and secondary markets early, then select bottle sizes that align with local requirements.

2. Brand Positioning: Premium vs Volume

Bottle size plays a direct role in brand perception. Premium whiskey brands often use standard sizes like 700ml or 750ml combined with heavier glass and refined proportions. Volume-driven brands may focus on 1L or 1.75L whiskey bottles, where value and cost per milliliter matter more.

For you, the right whiskey bottle size should support how you want the brand to be perceived, not work against it.

3. Distribution Channel

Where your whiskey is sold also influences bottle size selection. Duty-free and travel retail often favor 1L formats. Gift sets and promotions work better with 50ml or 200ml mini whiskey bottles. Core retail channels usually rely on standard glass whiskey bottle sizes for smoother logistics and shelf compatibility.

Matching bottle size to your distribution channel helps reduce friction throughout the supply chain.

4. Supply Chain Stability

Finally, consider how stable and scalable your packaging supply needs to be. Common whiskey bottle sizes are easier to source, refill, and reorder. Non-standard sizes may look unique but can increase lead time, tooling cost, and risk when demand grows.

For long-term planning, you should evaluate whether your chosen whiskey bottle size can support future expansion without frequent changes.

In the end, selecting a whiskey bottle size is not a single choice. It is a balance between regulation, brand strategy, distribution, and supply chain reliability. Brands that plan this early avoid costly adjustments later.

Can Whiskey Bottle Sizes Be Customized?

Yes, whiskey bottle sizes can be customized, but not every size offers the same level of flexibility. For you as a buyer or brand owner, understanding what can and cannot be adjusted helps avoid unexpected cost and delays.

Some standard whiskey bottle sizes are based on industry molds that are widely used across the market. Sizes such as 700ml and 750ml often fall into this category. These bottles follow fixed internal volumes and proven neck finishes, making them easier to source and refill at scale.

Other glass whiskey bottle sizes allow minor volume adjustments, usually within a range of ±10–30ml. This is commonly achieved by modifying the internal cavity or base thickness while keeping the external shape the same. These small adjustments can help you align with regional regulations or product positioning without developing a fully new bottle.

However, full customization usually requires new mold development, and this has a direct impact on minimum order quantity (MOQ). Custom molds increase tooling cost and typically come with higher MOQs to justify production setup. For small or early-stage brands, this can be a key consideration when choosing between standard and custom whiskey bottle sizes.

Another critical point is the neck finish. The neck finish determines which closures, caps, or corks can be used. Even small changes in bottle size or design may affect neck compatibility. This is why you should always confirm the neck finish with your glass bottle manufacturer early in the design process.

By understanding how whiskey bottle size customization works, you can make better decisions that balance design flexibility, compliance, and supply chain efficiency.

Conclusion

Different glass bottle sizes for whiskey serve different purposes across markets, channels, and brand stages. From 50ml mini bottles to 1.75L large formats, each size comes with its own regulatory requirements, structural considerations, and supply chain impact.

For brands, choosing the right whiskey bottle size is not only about volume. It is about compliance with target markets, alignment with brand positioning, distribution efficiency, and long-term supply stability. Standard sizes like 700ml and 750ml remain the most scalable options, while small or large formats require more careful planning.

By understanding how whiskey bottle sizes work in real-world production and distribution, you can reduce risk, control cost, and build a packaging strategy that supports your brand’s growth over time.

Frequently Asked Questions About Whiskey Bottle Sizes

1. What is the standard whiskey bottle size?

The most common standard whiskey bottle sizes are 750ml in the United States and 700ml in the European Union. These formats are widely accepted by regulators, filling lines, and distributors.

2. Why are there different whiskey bottle sizes in different countries?

Whiskey bottle size differences come from regional measurement systems and alcohol regulations. The US follows a 750ml standard, while the EU adopted 700ml under metric standardization rules.

3. Can I use the same whiskey bottle for both 700ml and 750ml?

In some cases, yes. Certain glass whiskey bottle designs can support both volumes by adjusting the internal cavity or base thickness. This must be confirmed with your glass bottle manufacturer to ensure filling accuracy and compliance.

4. What whiskey bottle sizes are best for export brands?

Export brands usually rely on 700ml and 750ml whiskey bottles for core retail products. Mini whiskey bottle sizes such as 50ml and 200ml are also suitable for global promotions and travel retail.

5. Are small whiskey bottle sizes suitable for new brands?

Yes. Sizes like 375ml and 500ml are commonly used by startup distilleries and craft brands. They support smaller batch production and lower inventory risk.

6. Do larger whiskey bottles break more easily during shipping?

Large whiskey bottle sizes such as 1L and 1.75L can have higher breakage risk if standard glass thickness is used. Reinforced structures and heavy base designs help improve transport safety.

7. Does customizing a whiskey bottle size increase MOQ?

In most cases, yes. Custom molds or non-standard whiskey bottle sizes usually require higher minimum order quantities compared to industry-standard sizes.

8. Why is neck finish important when choosing a whiskey bottle?

The neck finish determines closure compatibility. Even small changes in bottle size or design may affect which caps or corks can be used, so neck finish should be confirmed early in the design process.